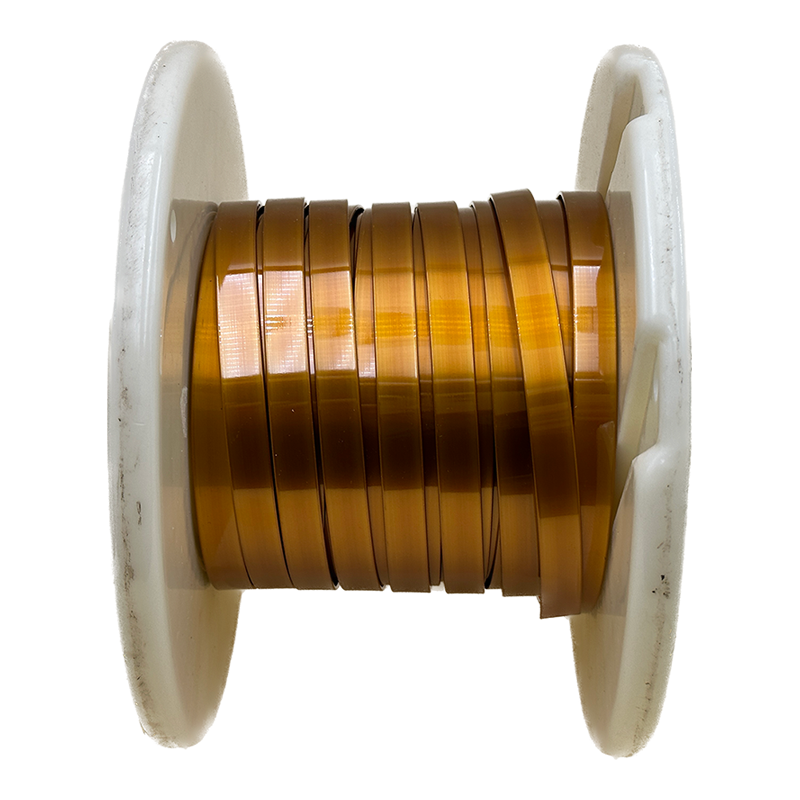

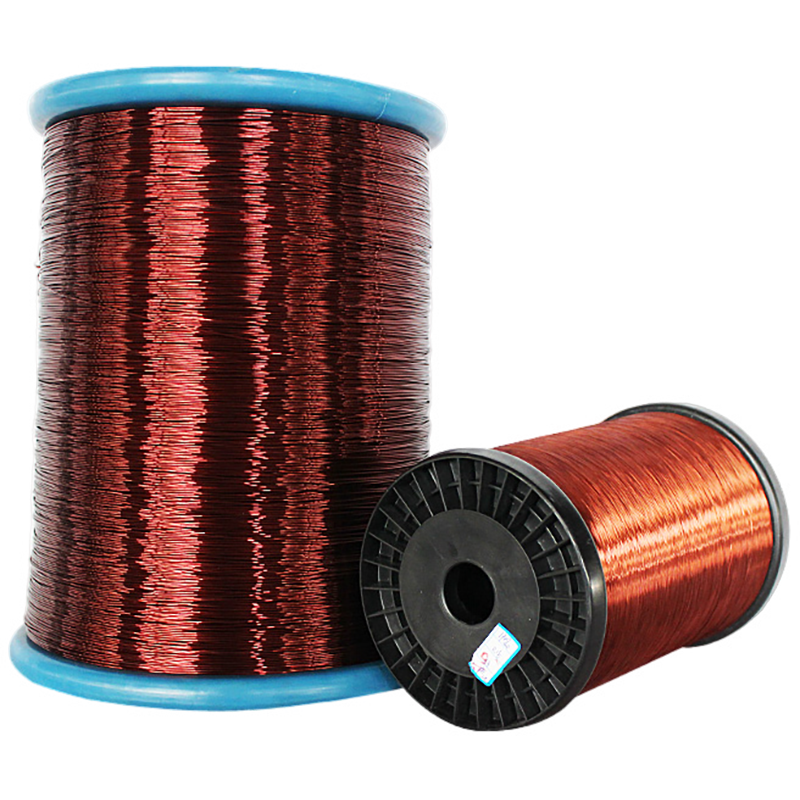

Product introduction: The cross-sectional area of edgewise winding enameled flat wire is ≥6mm². It is made by rectangular copper wire coated with high temperature insulating varnish. This product can meet the customer's different ways of winding, and it is widely used in transformers, motors, photovoltaic inverters and a variety of electrical equipment.

Product Category:

220 Polyamide-imide enamelled flat copper wire

220 Polyamide-imide enamelled flat aluminium wire

Standards:GB/T7095-2008

Production range:

Narrow side size a:0.80mm—5.00mm

Wide side size b:3.00mm—16.00mm

The recommended ratio of width and thickness: 1 < b/a < 20

If the use of specifications beyond the above range, please contact us.

The insulation thickness of enameled flat copper wire should meet the following requirements,

if you have special requirements for the insulation thickness , please contact us.

Insulation thickness grade | Insulation thickness mm | ||

| Min. | Nominal value | Max. | |

| 1 | 0.06 | 0.085 | 0.11 |

| 2 | 0.12 | 0.145 | 0.17 |

Enameled wire characteristics table

Flexibility of insulation: The insulation of the vertical winding enameled flat wire should be flexible at room temperature. Its wide side “a”,

and narrow side “b”should not cracked or peeled off when it is bending in the round bar by 180 degrees or winding by rectangular coil in table 1.

| a side size(mm) | Round bar diameter(mm) |

≥ 1.0 | 1a |

1.0 < a ≤ 2.00 | 2a |

2.0 < a ≤ 3.00 | 2a |

3.0 < a ≤ 4.00 | 3a |

b side size (mm) | Round bar diameter (mm) | Rectangular coil size (mm) |

≥ 6.0 | 2b | 15×40 |

6.0 < b ≤ 8.00 | 2b | 18×50 |

8.0 < b ≤ 10.00 | 3b | 20×60 |

10.0 < b ≤ 12.00 | 3b | 20×60 |

Thermal shock

The a (narrow) size and the b (wide) side of edgewise winding enameled flat wire bend according to table 2,and put into the heated oven bake for 1 hour,

the wire should be without cracking,the minimum thermal shock temperature should be 240℃

| a side size (mm) | a side bending size (mm) | b side size (mm) | b side bending size(mm) |

≥ 1.0 | 1a | ≥ 6.0 | 2b |

1.0 < a ≤ 2.00 | 2a | 6.0 < b ≤ 8.00 | 2b |

2.0 < a ≤ 3.00 | 2a | 8.0 < b ≤ 10.00 | 3b |

3.0 < a ≤ 4.00 | 3a | 10.0 < b ≤ 12.00 | 3b |