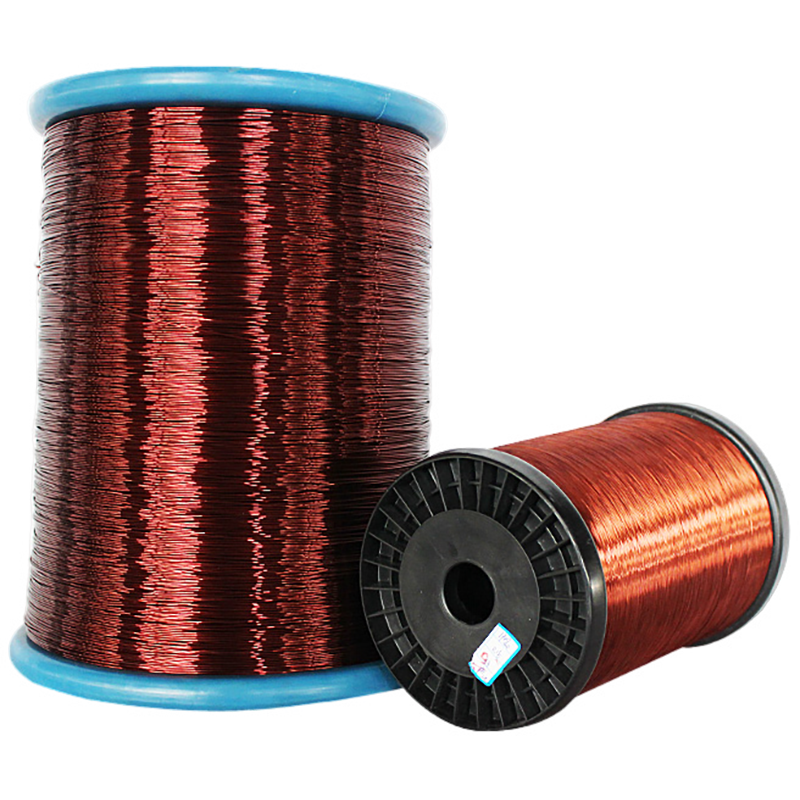

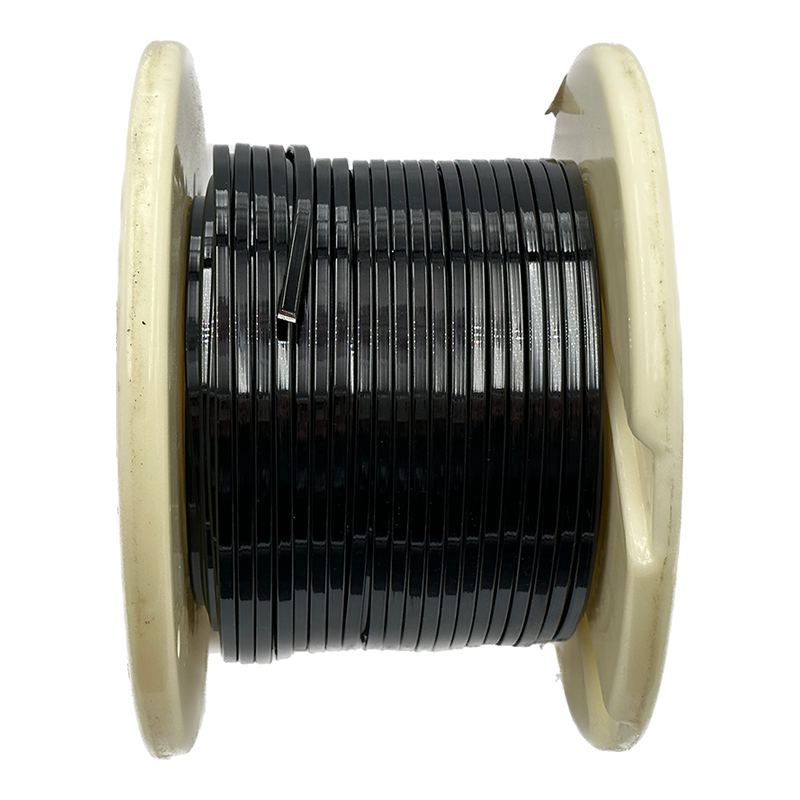

Enameled round copper wire is recognized for it's unique and beneficial qualities in electrical applications. We use the electrolytic copper ( Cu-ETP) with high purity(99.95%),which enables us to produce ultra fine wire down to a diameter of 10 microns. It's available size is in diameters from 0.010mm to 5.00mm(SWG5-40,AWG4-38) with different insulation, such as Polyurethane, Polyester, Polyesterimide, Polyimide etc..

The enamelled round aluminum wire reach to production standards: IEC60317,NEMA MW1000/JIS C3202.

1. 120 degree round enameled wire for oil-immersed transformer

2. 130, 155, 180 degree round enameled wire are widely used in all kinds of magnet coil

3. 200 degree round enameled wire works constantly in high temperature

4. 240 degree round enameled wire for magnet coils of aviation, military and marine application

Round Wire Diameter Range: 0.10mm to 5.00mm(SWG5-40,AWG4-38)

| Product Name | QZ-130 PEW130 | QZGB-155 PEW155 | QZ-180 EIW180 | Q(ZY/XY)-200 AI/ EIW200 | QY -240 AIW240 |

| Standard | IEC60317-3 GB/T6109.7 GB/T23312.3 | IEC60317-3 GB/T61019.2 GB/T23312.4 | MW 30 IEC60317–8 GB/T6109.5 GB/T23312.5 | MW 35 IEC60317–13 GB/T6109.20 GB/T23312.7 | MW 16 IEC60317-46 GB/T6109.22 |

| Thermal Class | 130℃ | 155℃ | 180℃ | 200℃ | 240℃ |

| Enamel Base Coat | Polyester | Modified Polyester | Polyester-Imide | Polyester-Imide | Polyimide |

| Enamel Top Coat | - | Polyamide-Imide | |||

| Cross Section Range | 0.1-5.0mm | 0.1-5.0mm | 0.1-5.0mm | 0.1-5.0mm | 0.1-5.0mm |

| Range of insulation thickness | IEC 60317-0-1 GB6108.2-85 | IEC 60317-0-1 GB6108.2-85 | IEC 60317-0-1 GB6108.2-85 | IEC 60317-0-1 GB6108.2-85 | IEC 60317-0-1 GB6108.2-85 |

| Performance | 1.excellent bendingproperty | 1.higher thermal property | 1.higher thermal property | 1.excellent thermal resistance | 1.excellent thermal resistance suitable for any electric equipments that are constantly exposed to high working temperature |

| Application | 1.dry & oil-immersed transformer | 1.dry & oil-immersed transformer | 1.winding of high and low voltage DC/AC motor | 4.winding of high and low voltage DC/AC motor | 1.winding with service temperature up to 220°C |

| Heat shock | 155℃ | 175℃ | 200℃ | 220℃ | 300℃ |